Key Concepts

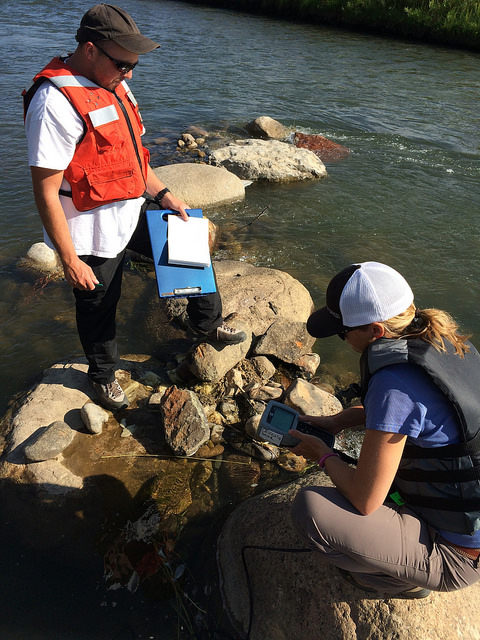

The division of engineering concerned with the environment and management of natural resources and the mitigation of environmental problems. The environmental engineer places special attention on the biological, chemical, and physical reactions in the air, land, and water environments and on improved technology for integrated management systems, including reuse, recycling, and recovery measures (Fig. 1). Environmental engineers are also involved in planning and policy development for zoning, regulatory, legal, and sustainability issues. See also: Conservation of resources; Environment

Scope

Environmental engineering began with the need for acceptable drinking water and for management of liquid and solid wastes. The earliest use of the terms public health and sanitary appears to have been in the 1800s, as efforts to identify solutions for eliminating water-borne disease began. Later, urbanization and industrialization contributed significantly to the formation of unsanitary conditions in many areas. Abatement of air and land contamination became new challenges for the environmental engineer, followed by toxic-waste and hazardous-waste concerns. The environmental engineer is also instrumental in the mitigation and protection of wildlife habitat, preservation of species, and the overall well-being of ecosystems. See also: Ecosystem; Public health; Water-borne disease

During project or product development, environmental engineers conduct a life-cycle analysis (cost-effectiveness analysis) of alternatives that consider the capital and the operation and maintenance costs over the life of the product. The National Environmental Policy Act and other legislation, regulations, and policies contain provisions to expand the alternative analysis to reduce ecological, health, and safety risks during development. This process embraces the concepts often called green engineering. See also: Green engineering

The U.S. Environmental Protection Agency (EPA) has a Design for the Environment (DfE) program that includes a life-cycle assessment. This process provides a tool to examine the environmental impacts of products over their entire life cycle from materials acquisition to manufacturing, use, and disposition. Design for the Environment provides decision-makers with information, tools, and incentives to make informed decisions that integrate risk, performance, and cost issues. The life-cycle analysis evaluates impacts on human health, atmospheric resources/air quality, water quality, ecological health, and natural-resource consumption.

Air-quality control

Generally, sources of air contaminants may be classified as stationary, mobile, or fugitive. Respectively, they are attributed to point sources such as industrial stack emissions, transportation activities such as automobile emissions, and uncontrolled (fugitive) sources such as windblown dusts from stockpiles. See also: Air pollution

The environmental engineer is instrumental in developing particulate and gas controls for all sources of air contaminants. Source control is the first abatement method considered. Controls for particulates include settling chambers, inertial separators, wet scrubbers, and fabric filters. Gas controls include absorption, adsorption, condensation, flaring, and incineration. Other areas of practice address acid rain issues, fugitive emissions, odor control, indoor air quality, and noise abatement. See also: Acid rain; Dust and mist collection; Gas absorption operations

Indoor air quality is of increasing concern for health officials and the public. Industrial hygienists and various engineering disciplines are instrumental in identifying and controlling indoor air pollution. Environmental engineering principles can be used in technical assessments for identifying air pollutants and selecting source controls. See also: Indoor air pollution

Indoor air quality control measures are very source-specific. The basic abatement strategies are source control, ventilation improvements, and air cleaners. Typically, source control is the most cost-effective abatement measure.

Water supply

Historically, the environmental engineer has found methods to provide ample quantities of quality drinking water for domestic use as well as quality water for commercial and industrial uses. Water-supply issues include demand projections, quality requirements, surface-water and ground-water source evaluations, groundwater production, surface-water collection and storage, surface-water treatment, saline-water treatment, nonconventional water production, and treated-water distribution. See also: Groundwater hydrology; Water resources; Water supply engineering

The typical surface-water treatment plant uses chemicals for enhancing removal of suspended solids and for disinfection. Physical treatment processes include simple settling and filtration. In sequence, the unit processes are rapid mix, coagulation, flocculation, sedimentation, filtration, and disinfection. Auxiliary systems are needed for chemical feed facilities and for sludge handling. Processes that are more specialized include carbon adsorption, ion exchange, and softening (Fig. 2). See also: Activated carbon; Water softening; Water treatment

Treatment of other sources generally requires site-specific determination of raw-water quality. Often, the quantity of demand will influence the cost-effective selection of treatment processes. Ground-water supplies require well development and treatment, such as aeration, softening, and disinfection. Likewise, brackish and saline waters require site-specific determination of treatment processes. Typical processes include membrane technology, such as reverse osmosis and electrodialysis. See also: Raw water; Water desalination

The water distribution system includes service and distribution lines, transmission mains, and storage facilities. Elevated storage tanks with gravity distribution and ground storage tanks with distribution pumping are designed to provide the quantity and pressure required to satisfy system demands.

Wastewater disposal

Wastewater is the combination of liquid- and water-transported wastes from homes, commercial buildings, industrial facilities, and institutions, along with any ground-water infiltration and surface-water and stormwater flow that may enter the sewer system. As a minimum measure, treatment is required for suspended solids and dissolved organics. Special processes may be necessary to achieve removal of specific pollutants, such as phosphorus from a municipal source or heavy metals from an industrial plating facility. See also: Industrial wastewater treatment; Sewage collection systems; Wastewater reuse

Minimum levels of treatment have been established by regulation. For example, in the United States 85% removal of oxygen-demanding organics and suspended solids followed by disinfection is the minimum level of treatment for domestic wastewaters. Additional treatment is dictated by the assimilative capacity of the receiving stream and by downstream water uses. See also: Sewage treatment

Physical processes are used to remove suspended solids that may damage or interfere with subsequent pumping and treatment units. Screens remove debris and other large solids, and gravity or aerated grit chambers capture sandy matter. Normally, gravity sedimentation is used to remove finer (organic) suspended solids. For special applications, centrifugation, dissolved air flotation, and filtration are used to remove suspended solids. See also: Centrifugation; Filtration; Flotation

Dissolved organics generally are treated with biological processes. The more common systems are aerobic (with oxygen) and include aerobic-pond, trickling-filter, and activated-sludge processes. Concentrated wastes, such as primary sludges, or high-strength industrial wastewaters, such as meat-processing or brewery wastes, are considered for anaerobic (without oxygen) treatment processes. Sludges, principally from biological processes, require special handling. The sequence of processes includes stabilization, conditioning, dewatering, drying, and residual disposal. Land application and landfilling are the most practiced means of final disposal. Special concerns for land-applied and composted sludges arise because of the concentrating of contaminants, such as heavy metals, and presence of pathogens in these sludges. See also: Sewage solids

Of the many other types of treatment process, one of the most important is natural systems, which historically included pond systems and, later, various modes of land application. Through technology, natural and constructed wetlands can provide high-quality effluents. See also: Wetlands

Stormwater management

While the study of stormwater management includes all elements of the hydrologic cycle, it focuses on how humans affect the production, movement, and control of surface runoff. In a natural system, the rate of surface runoff is controlled by the rainfall rate, soil conditions, vegetation, and subsurface geology. See also: Hydrology

Urbanization creates large impervious areas that increase the quantity and peak rate of runoff. Rainfall then washes deposited materials directly into surface waters, causing stream pollution. Organics create oxygen demands, nutrients accelerate lake eutrophication, and heavy metals accumulate in bottom sediments. See also: Eutrophication; Water pollution

Environmental engineers apply modern stormwater management practices to use natural and engineered systems to minimize environmental damage. A complete stormwater management program contains many elements, including on-site infiltration and detention, collection and transport systems, regional flood control, and major stream-channel improvements. See also: Groundwater recharge; River engineering

In the past, sanitary wastes and stormwater were collected in the same (combined) sewer. During heavy rainfalls, the sewers would overflow, creating water pollution problems. Many of these combined sewers have been separated, while the remaining overflows are treated as point sources. Stormwater management practices are used to lessen the requirements and costs for combined sewer overflow treatment facilities.

Solid-waste management

The collection, transport, processing, and disposal of solid wastes is an important area of environmental engineering. Solid wastes are those materials that are deemed by their owner to possess no value and are discarded. They are generated by almost every activity, and the amount varies by source, season, geography, and time. As land becomes more limited and regulation increases, the solid-waste generator and handler must employ new and improved technology to reduce the quantities of materials requiring disposal. Furthermore, recovery and reuse are important elements of solid-waste management.

Historically, solid-waste disposal consisted of open dumping. However, the modern method of disposal uses double-lined landfills with collection and controls for gases and leachate. Other disposal means include composting and various incineration processes, which also may be used for co-disposal of wastewater treatment sludges. These disposal means typically require controls for created pollutants, such as leachate and odor from compost operations, and chemical and particulate emission from incinerator combustion.

Recovery and reuse are practiced widely. Source or central-facility separation is used for a variety of products, including paper, glass, plastics, ferrous metals, and nonferrous metals. Also, refuse-derived fuels may be used for energy production, and yard wastes may be composted to produce a humus soil conditioner. See also: Recycling technology

Integrated solid-waste management plans include recovery and reuse as essential elements. Source reduction techniques and cost-effective recovery of solid wastes for reuse in industrial production improve energy recovery and production, provide direct economic benefits, and lessen the overall requirements for solid-waste processing and disposal.

Source reduction is a priority pollution prevention measure and includes design, manufacture, or use of materials to reduce the amount and/or toxicity of materials before they enter the solid-waste management process. Examples include managing nonproduct organic wastes such as food scraps and yard trimmings, extending the useful life of products to postpone disposal, designing packaging to reduce the quantity for waste disposal, reusing existing products or packaging, and segregating and collecting waste materials onsite for recycle at residential, commercial, and manufacturing generator sites.

Principal energy recovery technologies are incineration furnace walls with integrated boiler tubes (waterwalls); modular incineration with heat recovery boilers or heat exchangers; refuse-derived fuels for co-fired or dedicated boilers; pyrolysis into gaseous, liquid, or solid fuels; and anaerobic digestion or landfill gas recovery for methane fuel development. See also: Cogeneration systems; Heat exchanger; Pyrolysis; Waste-to-energy

Hazardous-waste management

Whether they are pesticides from agricultural lands, gasoline leaks from service stations, heavy metals from plating solutions, medical wastes from hospitals, or radioactive wastes from nuclear power plants, hazardous wastes are present throughout the world as by-products of growth in developing nations. They pose unreasonable risks to human health and safety, property value and use, and all other components of the environment (Fig. 3). See also: Hazardous waste; Radioactive waste management

Hazardous-waste treatment involves liquid-waste treatment, solid-waste treatment, solidification and stabilization, thermal destruction, and land disposal. Remedial action is characterized as surface-water control, air-pollution control, or in-place treatment. See also: Hazardous waste engineering

A significant portion of the technology for the treatment and disposal of hazardous wastes is refinement or adaptation of proven practices in air-quality control, wastewater treatment, and solid-waste management. Also, the environmental engineer must understand hydrogeology to assess the subsurface disposition of hazardous wastes.

At a hazardous-waste treatment or disposal site, the routes of the waste into the environment must be obstructed. Principal routes include surface-water contamination from runoff or overflows; ground-water contamination from leaks or leachate; air contamination from open burning, evaporation, or fugitive dusts; fire and explosion; and health risks from human contact.

EPA regulations define hazardous wastes in specific lists based on characteristics of ignitability, corrosivity, reactivity, and an analytic procedure known as EP toxicity. Household wastes, domestic sewage, and certain other wastes are excluded from these regulations. In the United States, regulations for hazardous wastes include requirements of a manifest system for tracking wastes from generators through storage, transport, treatment, and disposal. In addition to treatment and disposal, it is necessary to provide the means to satisfy these regulatory controls as well as means of pollution prevention using waste reduction through process changes, including recovery and reuse.