Key Concepts

The component of a motor vehicle that converts the chemical energy in fuel into mechanical energy for power. The internal combustion engine also drives the generator and various accessories, such as the air-conditioning compressor and power-steering pump. See also: Automobile; Automotive climate control; Automotive electrical system; Automotive steering

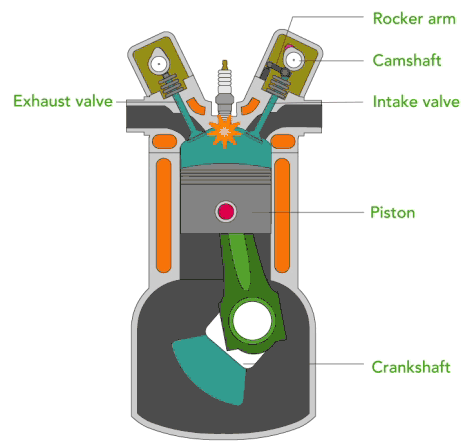

The flexibility of an internal combustion engine operating on the four-stroke Otto cycle remains the dominant automotive power plant in conventional and hybrid electric vehicles. It is a gasoline-burning, liquid-cooled, spark-ignition, multi-stroke-cycle, multicylinder engine (see illustration). Alternative fuels are being investigated, however. The engine has the intake and exhaust valves in the cylinder head, and electronically controlled ignition and fuel injection. An Otto-cycle engine is an internal combustion piston engine that may be designed to operate on either two strokes or four strokes of a piston that moves up and down in a cylinder. Generally, the automotive engine uses four strokes to convert chemical energy to mechanical energy through combustion of gasoline or similar hydrocarbon fuel. The heat produced is converted into mechanical work by pushing the piston down in the cylinder. A connecting rod attached to the piston transfers this energy to a rotating crankshaft. See also: Alternative fuels for vehicles; Combustion chamber; Engine; Gasoline; Otto cycle

Automotive internal combustion engines having from 1 to 16 cylinders in in-line, flat, horizontally opposed, or V-type cylinder arrangements have appeared in production vehicles. Increased vehicle size and weight played a major role in this transition, requiring engines with additional displacement and cylinders to provide acceptable performance.

In many automotive engines, the camshaft, which operates the intake and exhaust valves, has been moved from the cylinder block to the cylinder head. This overhead-camshaft arrangement allows the use of more than two valves per cylinder, with various multivalve engines having three to five. Some overhead-camshaft engines have only one camshaft, while others have two camshafts, one for the intake valves and one for the exhaust valves. A V-type engine may have four camshafts, two for each bank of cylinders.

Most engines have fixed valve timing, regardless of number of camshafts or their location. Variable valve timing can improve fuel economy and minimize exhaust emissions, especially on multivalve engines. At higher speeds, volumetric efficiency can be increased by opening the intake valves earlier. One method drives the camshaft through an electrohydraulic mechanism that, on signal from the engine computer, rotates the intake camshaft ahead about 10°. Another system varies both valve timing and valve lift by having two cam lobes, each with a different profile, that the computer can selectively engage to operate each valve. Computer-controlled solenoids for opening and closing the valves will allow elimination of the complete valve train, including the camshaft, from the automotive piston engine while providing variable valve timing and lift.

Historically, major engine components have been made from ferrous metals, either by casting or by forging. However, emphasis on weight reduction for improved fuel economy has greatly increased the usage of aluminum for cylinder blocks, cylinder heads, and other engine components. Some engine covers and intake manifolds are made of magnesium. Internal engine parts, such as connecting rods, sprockets, oil-pump rotors, and valve guides, are cast or forged to nearly net shape using powder metallurgy. High-speed engines may use titanium connecting rods to reduce reciprocating mass. See also: Powder metallurgy

Parts such as engine covers, intake manifolds, and oil pans also can be fabricated of plastic or composite materials. These materials provide weight savings while reducing engine noise and vibration. Ceramic engine parts and coatings will allow engine operation at higher temperatures, raising engine efficiency. Ceramic-lined exhaust ports in the cylinder head can lower its temperature while increasing the effectiveness of the catalytic converter. See also: Catalytic converter