Reusable sponge-like (foam) sorbent materials for cleaning up oil spills may soon become available, as a result of promising research from multiple groups. Oil spills damage ecosystems and habitats, harm and kill wildlife and plants, contaminate drinking water, and endanger public health and safety. According to the U.S. Environmental Protection Agency (EPA), an estimated 10 to 25 million gallons of oil are spilled each year in the United States. See also: Foam; Oil spill; Petroleum; Petroleum products

Oil spilled in bodies of water may be removed by combustion or collection. Combustion is a highly efficient means of oil removal in the open ocean but must be done soon after the spill; otherwise, the oil will become emulsified with water and difficult to ignite. Collection is done by using oil-skimming boats and sorbents. Sorbents, both natural and synthetic, are available as particulates, mats, or booms and can absorb oil spilled on land or in water. See also: Absorption

Single-use sorbent materials are effective in cleaning up oil spills because they can absorb up to 70 times their weight in oil. For large-volume oil spills, however, their use becomes costly. For disposal, these sorbents must be incinerated, along with the collected oil. Reusable sorbent materials not only have the potential to reduce cleanup costs, but they also could allow for oil recovery.

Researchers at the Argonne National Laboratory have developed a polymeric foam, called the Oleo Sponge, that can absorb up to 90 times its weight in oil and then be reused up to 100 times after being mechanically squeezed to expel the oil. To accomplish this, the researchers treated the inner surfaces of commercially available polyimide or polyurethane foams with a metal oxide to which they attached silane molecules, which have a high affinity for oil. Tests in a seawater tank at the National Oil Spill Response Research & Renewable Energy Test Facility in Ohmsett, New Jersey, demonstrated that the Oleo Sponge could absorb both diesel and crude oil on and below the water surface. See also: Heterocyclic polymer; Organosilicon compound; Oxide; Polyurethane resins

A reusable wood sponge that absorbs oil was developed by researchers at the Chinese Academy of Forestry. The wood sponge was made by chemically removing the lignin and hemicellulose from balsa wood to produce a porous cellulose structure. The cellulose structure was then coated with a polysiloxane material that attracts oil but not water. The wood sponge absorbed up to 41 times its weight in oil and maintained its structure after repeatedly being squeezed to expel the oil. Because it is made from renewable and degradable materials, the wood sponge could potentially be a more sustainable option for cleaning up oil spills. See also: Balsa; Cellulose; Hemicellulose; Lignin

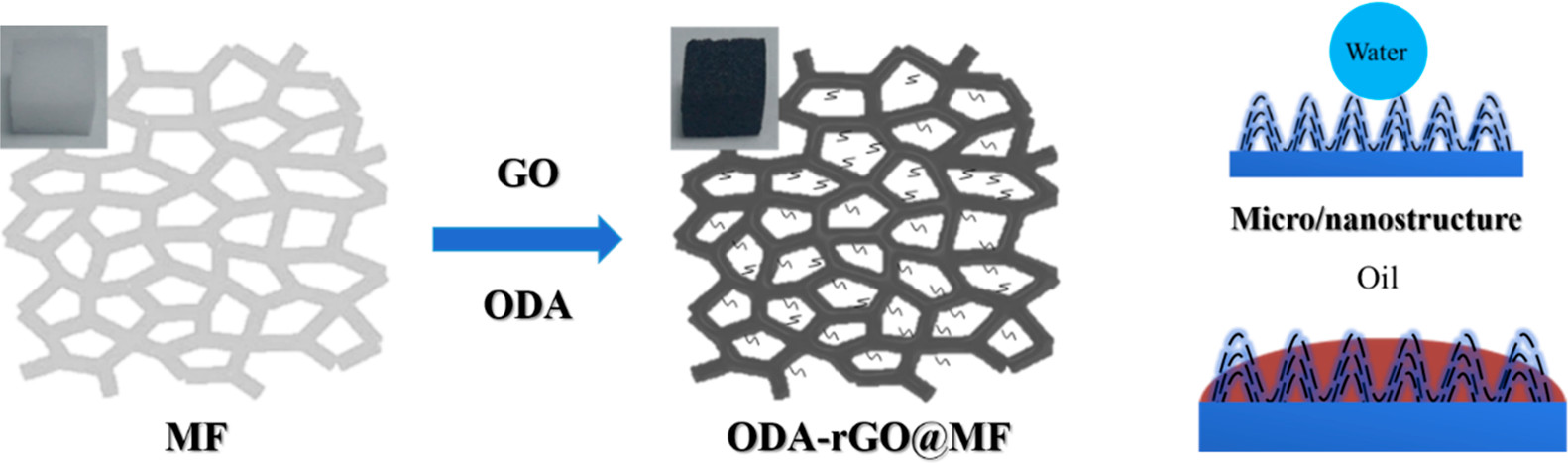

A further example of a reusable oil-absorbing foam, called ODA-rGO@MF, was reported by researchers at Zhejiang University, China. To make ODA-rGO@MF, the researchers coated a commercially available melamine foam (MF) with octadecylamine-grafted reduced graphene oxide (ODA-rGO). The ODA-rGO@MF foam absorbed up to 111 times its weight in oil and survived 100 absorbing-squeezing cycles. The researchers said that because the foam is made from inexpensive materials with a low-cost fabrication process, large-scale production should be feasible, making it a promising absorbent for oil-spill cleanups. See also: Amine; Graphene; Urea-formaldehyde resins