Roman marine concrete, having lasted for nearly 2000 years, is a highly durable material. In contrast, modern marine concrete, which is made using Portland cement, may start to degrade in as few as 50 years. Researchers have now discovered why. As reported in the journal American Mineralogist (July 2017), they described the composition of the concrete and the chemical reactions responsible for its longevity. See also: Cement; Concrete

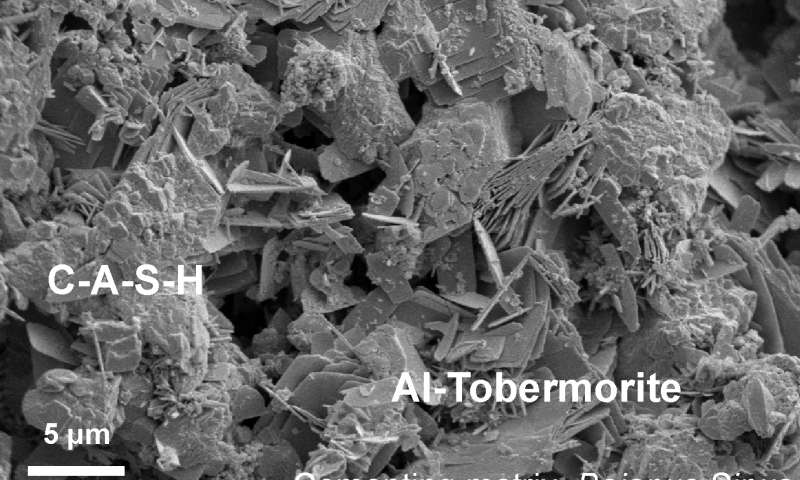

Concrete core samples analyzed from relic Roman sea walls and harbor piers contained volcanic rock cemented in a mortar consisting of volcanic ash that had reacted with calcium hydroxide. This alone was not surprising because historical Roman records indicate that the concrete was made using volcanic ash, lime (calcium oxide), and seawater, mixed with volcanic rocks. In such a material, the silicates of the volcanic ash react with calcium hydroxide to form a calcium-aluminum-silicate-hydrate (C-A-S-H) cementitious binder. However, the durability of the concrete was generated years later as seawater infiltrated the concrete and reacted with phillipsite, a mineral component of the volcanic ash, to from Al-tobermorite crystals. The researchers believe that these platy Al-tobermorite crystals resist fracturing as well as prevent cracks from spreading in Roman concrete. See also: Lime (industry); Mortar; Pyroclastic rocks; Tuff; Volcano

In addition to the implications for materials scientists developing more durable concrete products based on these findings, Roman concrete was produced using much less energy than concrete made using Portland cement. For every metric ton (tonne) of Portland cement produced, 0.8 to 1.0 tonnes of carbon dioxide are emitted into the atmosphere. Using volcanic ash or other materials containing a similar mineral composition in concrete mixtures could lead to environmentally friendlier and more durable products. See also: New generation of concretes; Structural materials