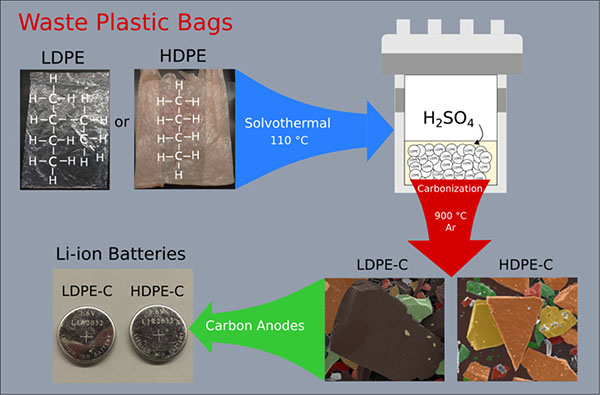

Researchers have produced carbon chips from waste plastic bags for use in making anodes for lithium-ion batteries, according to a report in ACS Omega (December 2018). For the most part, it is very difficult to break down (depolymerize) plastics into their original monomers, other smaller useful compounds, or even carbon. For example, polyethylene (PE) that has been heated above its melting point does not break down into ethylene monomer or carbonize. Instead, PE decomposes into gases such as carbon dioxide (CO2), carbon monoxide (CO), water (H2O), and low-molecular weight hydrocarbons. To carbonize waste PE, the researchers had to come up with a novel process. See also: Battery; Carbon; Plastic waste pollution; Polymer; Polyolefin

In this process, the researchers added sulfonic acid (SO3H) groups to the PE by heating waste plastic bags in sulfuric acid for 12 hours at 110°C, which is just below the bags’ melting point of 115–135°C. Then, they carbonized the sulfonated PE by heating it in a furnace for two hours at 900°C. During this high-temperature stage, the sulfonated PE crosslinked at around 500°C, allowing it to decompose into carbon chips. The resulting carbon chips were ground into a fine powder that was used to formulate lithium-ion-battery anodes composed of 80 percent carbon derived from PE, 10 percent poly(vinylidene difluoride), and 10 percent carbon black. The performance of the lithium-ion coin and button-cell batteries that incorporated the experimental anodes was comparable to commercial batteries. See also: Sulfuric acid

Plastic products, such as PE plastic shopping bags, often have a useful life of only minutes. Plastics also are also imperishable; that is, they do not biodegrade. Over time, plastics break down into smaller and smaller pieces in the environment. These pieces may release toxic additives that enter the food chain, particularly in the ocean. At present, the quantity of plastics recycled, reused, or repurposed is very low. Using PE bags to make lithium-ion battery anodes will not solve the plastic-waste problem, but such projects demonstrate the feasibility of developing fairly simple first steps toward dealing with the problem. See also: Recycling technology