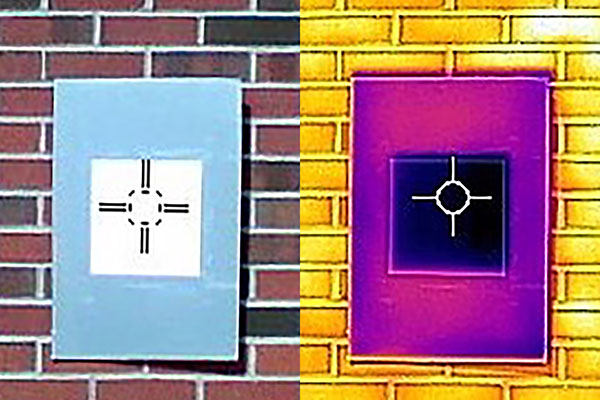

Researchers at Purdue University in Indiana, United States, have developed the whitest white paint on record, based on its ultrahigh reflection rating. By incorporating a pigment called barium sulfate (BaSO4) at the highest concentration possible, the paint reflected up to 98 percent of sunlight. In contrast, most commercial white paints use the pigment titanium dioxide (TiO2) and reflect only about 80 percent of sunlight. This high reflection quotient helps keep painted surfaces much cooler. Surfaces coated with the new paint remained 4.5°C (8.1°F) cooler than the surrounding uncoated surfaces when exposed to midday sunlight, whereas the temperature of surfaces coated with a commercial white paint increased by 6.8°C (12.2°F) when exposed to the same conditions. See also: Barium; Paint and coatings; Pigment (material); Reflection of electromagnetic radiation; Solar radiation; Titanium oxides

Barium sulfate pigments have been used in paints for more than 100 years, but the key to making the whitest white paint was in determining the optimum size and size range of BaSO4 nanoparticles. Researchers then incorporated the tiny particles into an acrylic polymer binder at 60 percent by weight of the paint’s dry-film composition, which was the highest concentration possible before the mechanical properties of the paint degraded. See also: Nanoparticle

If commercialized, researchers believe that the paint could be used on roofs to cool buildings in most places that experience hot summers, thereby reducing the need for air conditioning and, as a result, reducing carbon dioxide emissions from energy use. The paint could also help mitigate the effects of climate change in hot regions, where people may or may not have access to air conditioning. See also: Air conditioning; Deadly heat in an era of global climate change; Global climate change