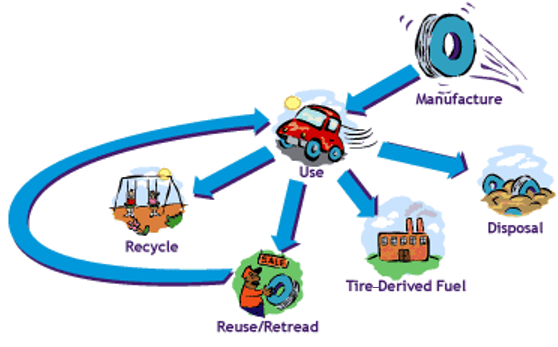

Scrap tires are a common waste material, although markets do exist. According to the U.S. Tire Manufacturers Association, of the roughly 270 million scrap rubber tires generated each year in this country, about 100 million tires are used as fuel; about 66 million tires are ground up and recycled in asphalt or molded and extruded into various parts; and about 64 million tires are used in miscellaneous applications. The remaining 40 million scrap tires—representing about 15 percent of the total—are disposed of in landfills. Adding to this economic and ecological burden, scrap tires can release hazardous chemicals, including heavy metals, into the environment. See also: Recycling technology; Rubber; Tire

Researchers from Rice University in Texas, United States, may have found a way to reduce these enviroeconomic burdens. As reported in the journal Carbon (April 2021), the scientists identified a potential use of rubber from scrap tires that would otherwise be burned as fuel or disposed of in landfills. Using a process called Joule heating, which heats carbon-containing materials to 2760 degrees Celsius (5000 degrees Fahrenheit) in less than a second, the team generated a graphene product they called “flash graphene.” In the Joule heating process, an electric current is passed through a material and produces heat very quickly. The researchers estimate that the electricity for upcycling a ton of tire rubber to flash graphene would cost about US$100, which would be quite economical. See also: Electric current; Graphene; Heat; Joule's law

Graphene itself—a two-dimensional sheet of carbon atoms arranged in a honeycomb structure—is known to have many potential applications in electronics because of its conductivity. Adding small amounts of graphene to other materials, such as metals and plastics, has been found to enhance the strength of these materials, thereby reducing the quantity of material needed for production. The Rice researchers discovered that adding as little as 0.1 percent of flash graphene in cement used to produce concrete increased the concrete’s strength by 30 percent. Concrete is the most widely used construction material worldwide. However, cement production requires a great deal of energy and, as a result, is accountable for about eight percent of annual worldwide atmospheric emissions of the greenhouse gas carbon dioxide (CO2). Strengthening concrete with graphene could potentially allow manufacturers to conserve up to one-third the amount of concrete typically used in construction applications. Consequently, upcycling scrap tires to graphene for enhancing the strength of concrete could also have a significant impact on slowing global warming. See also: Carbon; Carbon dioxide; Cement; Concrete; Conduction (electricity); Global warming; Greenhouse effect